Measurement Trains & Systems

Track Measurement

Automated optoelectronic system for precise track parameter measurement, enabling real-time data analysis and predictive maintenance.

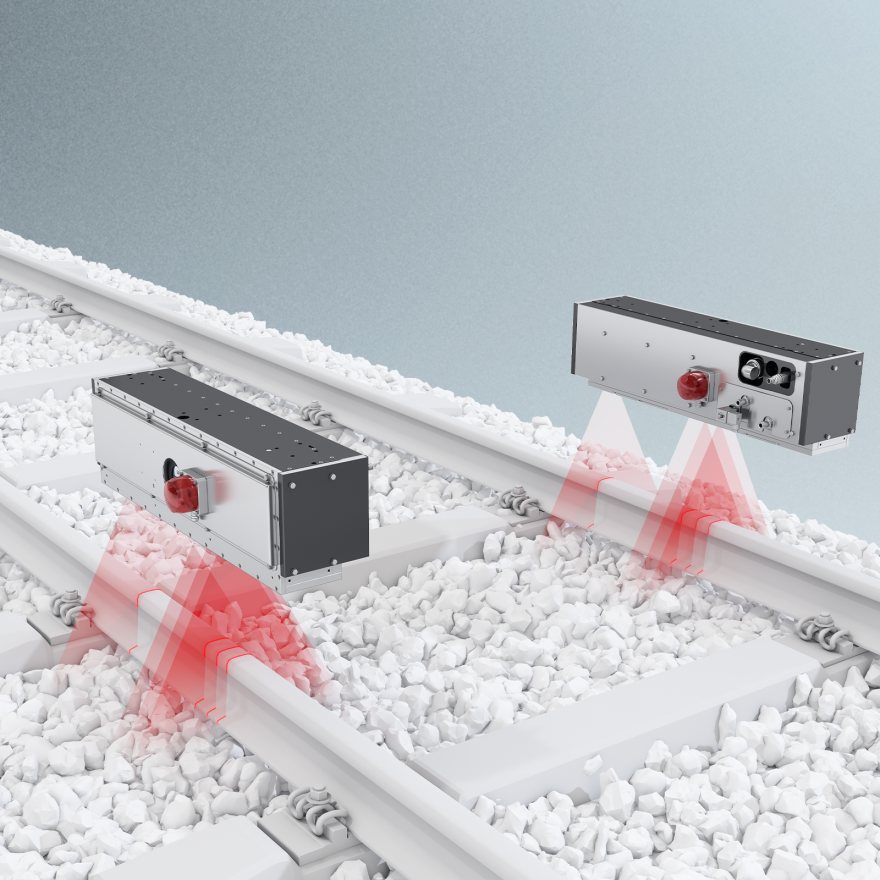

Track Geometry

Track geometry is a key parameter in track condition, influencing degradation phenomena and guiding maintenance and repair activities. The permanent way faces numerous factors affecting its condition and safety. Proper maintenance ensures significant benefits. Automated optoelectronic systems enable precise 3D measurement of track geometry, supporting design and construction processes.

A compact no-contact system evaluates track geometry at speeds up to 400 km/h, using an inertial unit with accelerometers, gyroscopes, and optical-gauge boxes. Its modular design supports full rail profile measurement and unattended operation.

Optical sub-systems on a vehicle enable chord-based track geometry measurement at speeds up to 320 km/h, using advanced non-contact technology. The system detects and reports defects in real-time, with thresholds configurable by the user.

Track Geometry

Track geometry is a key parameter in track condition, influencing degradation phenomena and guiding maintenance and repair activities. The permanent way faces numerous factors affecting its condition and safety. Proper maintenance ensures significant benefits. Automated optoelectronic systems enable precise 3D measurement of track geometry, supporting design and construction processes.

A compact no-contact system evaluates track geometry at speeds up to 400 km/h, using an inertial unit with accelerometers, gyroscopes, and optical-gauge boxes. Its modular design supports full rail profile measurement and unattended operation.

Optical sub-systems on a vehicle enable chord-based track geometry measurement at speeds up to 320 km/h, using advanced non-contact technology. The system detects and reports defects in real-time, with thresholds configurable by the user.

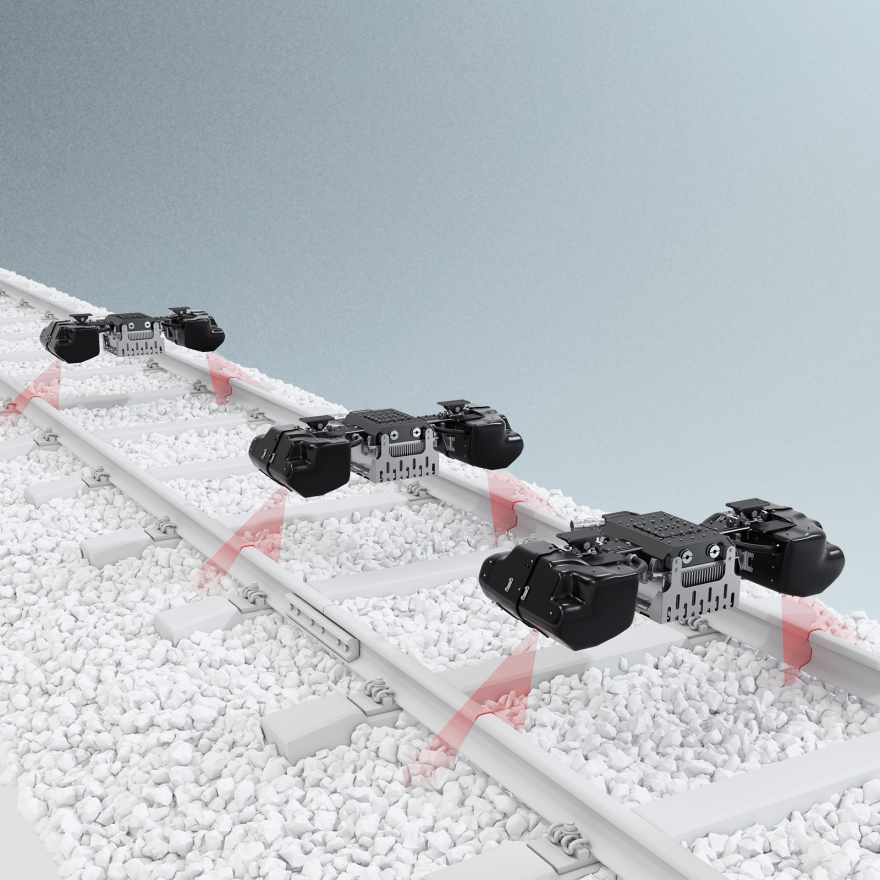

Turnout & Crossing Measurement System

Switches and Crossings (S&C), with moving parts, endure high forces and vibrations, requiring proper care for optimal performance. Advanced optoelectronic systems accurately measure 3D switch geometry and profiles at high speeds with minimal track possession. A compact, no-contact system with inertial units, optical boxes, and linear cameras evaluates all critical S&C parts at speeds up to 240 km/h, providing precise measurements and high-resolution images for analysis.

Turnout & Crossing Measurement System

Switches and Crossings (S&C), with moving parts, endure high forces and vibrations, requiring proper care for optimal performance. Advanced optoelectronic systems accurately measure 3D switch geometry and profiles at high speeds with minimal track possession. A compact, no-contact system with inertial units, optical boxes, and linear cameras evaluates all critical S&C parts at speeds up to 240 km/h, providing precise measurements and high-resolution images for analysis.

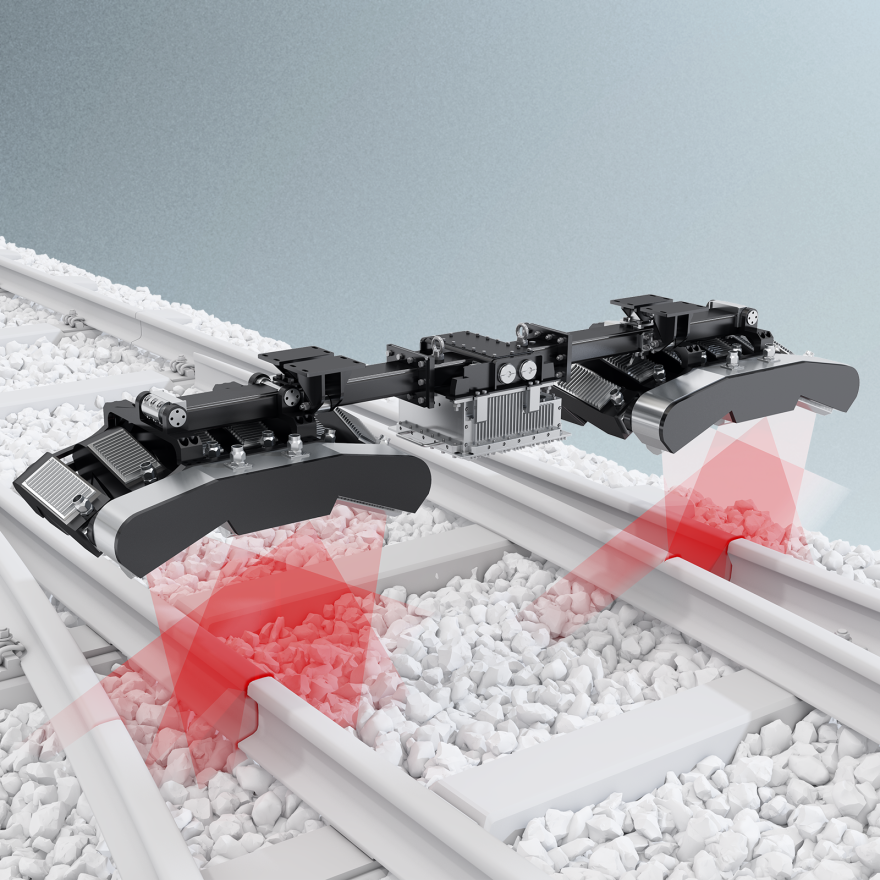

Rail Profile

The rise in railway speeds necessitates stricter rail profile control, as rail wear is critical for infrastructure safety. Key measurements, including head width, crown radius, and wear on the top and sides, are assessed by comparing with standard profiles. Full rail head cross-sections enable precise horizontal and vertical wear calculations.

Integrated with Track Geometry, Full Rail Profile uses lasers and cameras for precise, real-time rail profile and wear analysis at track speeds. Cameras capture full cross-sections from base to top, enabling comprehensive measurements and seamless parameter integration.

A high-performance system aids rail grinding by comparing templates and measuring worn areas at track speeds. It automatically identifies rail types and provides grinding reports upon request, streamlining maintenance and operations.

Rail Profile

The rise in railway speeds necessitates stricter rail profile control, as rail wear is critical for infrastructure safety. Key measurements, including head width, crown radius, and wear on the top and sides, are assessed by comparing with standard profiles. Full rail head cross-sections enable precise horizontal and vertical wear calculations.

Integrated with Track Geometry, Full Rail Profile uses lasers and cameras for precise, real-time rail profile and wear analysis at track speeds. Cameras capture full cross-sections from base to top, enabling comprehensive measurements and seamless parameter integration.

A high-performance system aids rail grinding by comparing templates and measuring worn areas at track speeds. It automatically identifies rail types and provides grinding reports upon request, streamlining maintenance and operations.

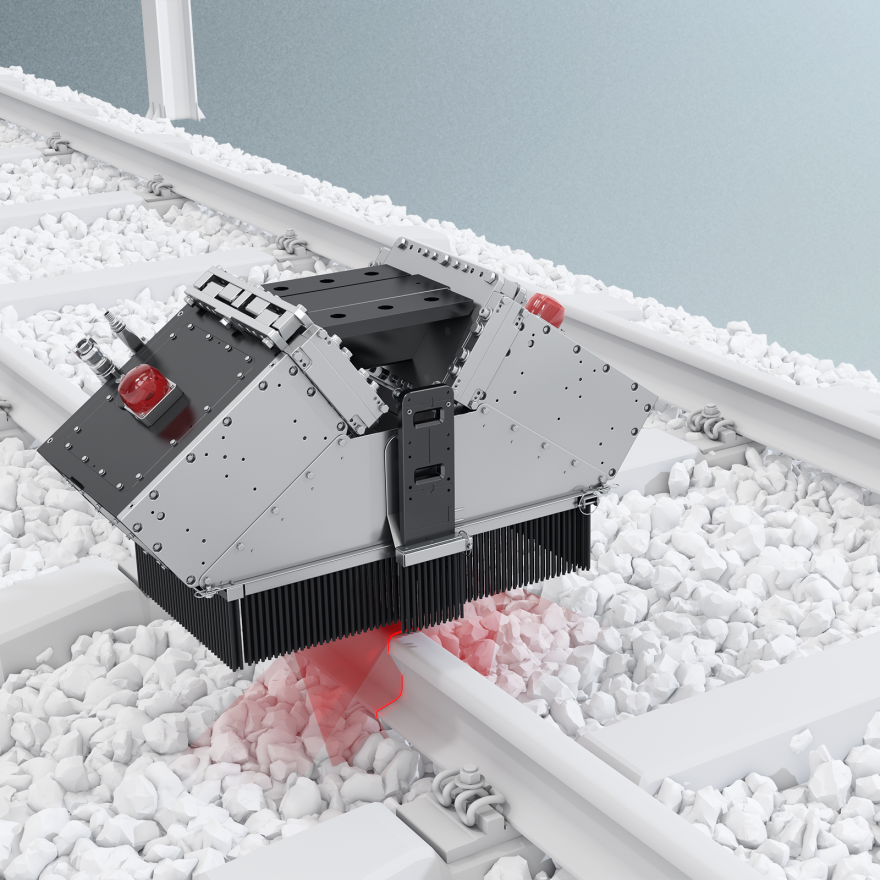

Rail Corrugation

Defects cause a harmful cycle, spreading issues to wheels and lower infrastructure, leading to dynamic forces that deteriorate fastenings, sleepers, and ballast, reducing track and vehicle lifespan. Laser-based systems analyze corrugation across critical wavelengths, detecting longitudinal defects with precision at any speed.

MERMEC Rail Corrugation Systems (RCS) measure rail corrugations (10-3000 mm wavelengths) using cameras and lasers with Versine transfer function. Operating at speeds up to 160 km/h, in all conditions, it provides real-time analysis, storage, and grinding validation with micrometer accuracy.

The system uses inertial and inductive measurements to assess rail surface conditions at speeds up to 320 km/h, in all weather, and both directions. It provides real-time data acquisition, storage, and visualization, with post-processing for detailed analysis and standard deviation calculations.

Rail Corrugation

Defects cause a harmful cycle, spreading issues to wheels and lower infrastructure, leading to dynamic forces that deteriorate fastenings, sleepers, and ballast, reducing track and vehicle lifespan. Laser-based systems analyze corrugation across critical wavelengths, detecting longitudinal defects with precision at any speed.

MERMEC Rail Corrugation Systems (RCS) measure rail corrugations (10-3000 mm wavelengths) using cameras and lasers with Versine transfer function. Operating at speeds up to 160 km/h, in all conditions, it provides real-time analysis, storage, and grinding validation with micrometer accuracy.

The system uses inertial and inductive measurements to assess rail surface conditions at speeds up to 320 km/h, in all weather, and both directions. It provides real-time data acquisition, storage, and visualization, with post-processing for detailed analysis and standard deviation calculations.

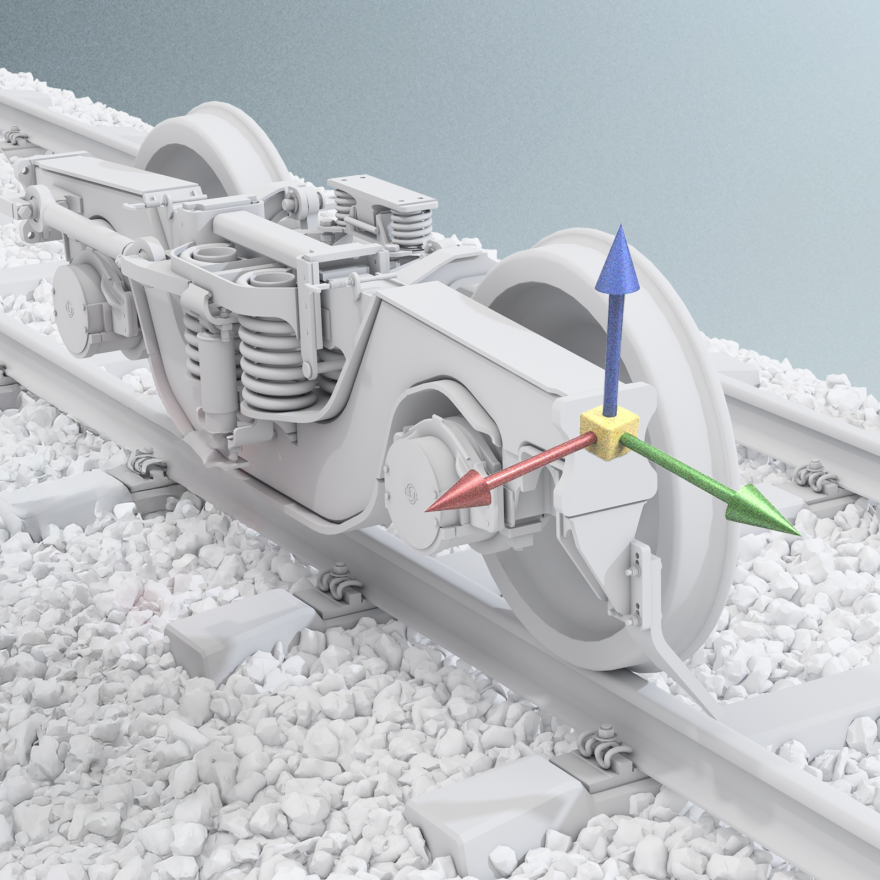

Inertial-Based Ride Quality

Low vibrations can significantly impact passengers’ sedentary activities. The Ride Quality Measurement System uses accelerometers on the axle box, bogie, and vehicle body to monitor vertical and transversal accelerations at various suspension levels. It analyzes dynamic behavior, ensuring safety and ride quality by calculating indexes like Ride Quality per UIC 518 standards, providing precise, automated real-time data even at high speeds.

Inertial-Based Ride Quality

Low vibrations can significantly impact passengers’ sedentary activities. The Ride Quality Measurement System uses accelerometers on the axle box, bogie, and vehicle body to monitor vertical and transversal accelerations at various suspension levels. It analyzes dynamic behavior, ensuring safety and ride quality by calculating indexes like Ride Quality per UIC 518 standards, providing precise, automated real-time data even at high speeds.

Tunnel & Clearance: T-Sight 400

Clearance gauge measurement is crucial for railway safety, preventing damage from objects entering restricted areas. The T-Sight 400 system uses rotating lasers and machine vision to scan 360° profiles, detecting clearance violations in real-time and alerting maintenance staff. It inspects tunnels, bridges, poles, walls, and obstacles, ensuring safe rail transport. Its modular design integrates with video systems for digital line monitoring when parameters exceed thresholds.

Tunnel & Clearance: T-Sight 400

Clearance gauge measurement is crucial for railway safety, preventing damage from objects entering restricted areas. The T-Sight 400 system uses rotating lasers and machine vision to scan 360° profiles, detecting clearance violations in real-time and alerting maintenance staff. It inspects tunnels, bridges, poles, walls, and obstacles, ensuring safe rail transport. Its modular design integrates with video systems for digital line monitoring when parameters exceed thresholds.

How can we help you?

We’re here to support you. Whether you have questions about MERMEC solutions or need specific information, our team is ready to assist. Reach out to us, and we’ll ensure you get the answers and guidance you need.

Get in touch