Measurement Trains & Systems

Track Inspection

In-motion, contactless system capturing multiple parameters to identify over 50 track defect types.

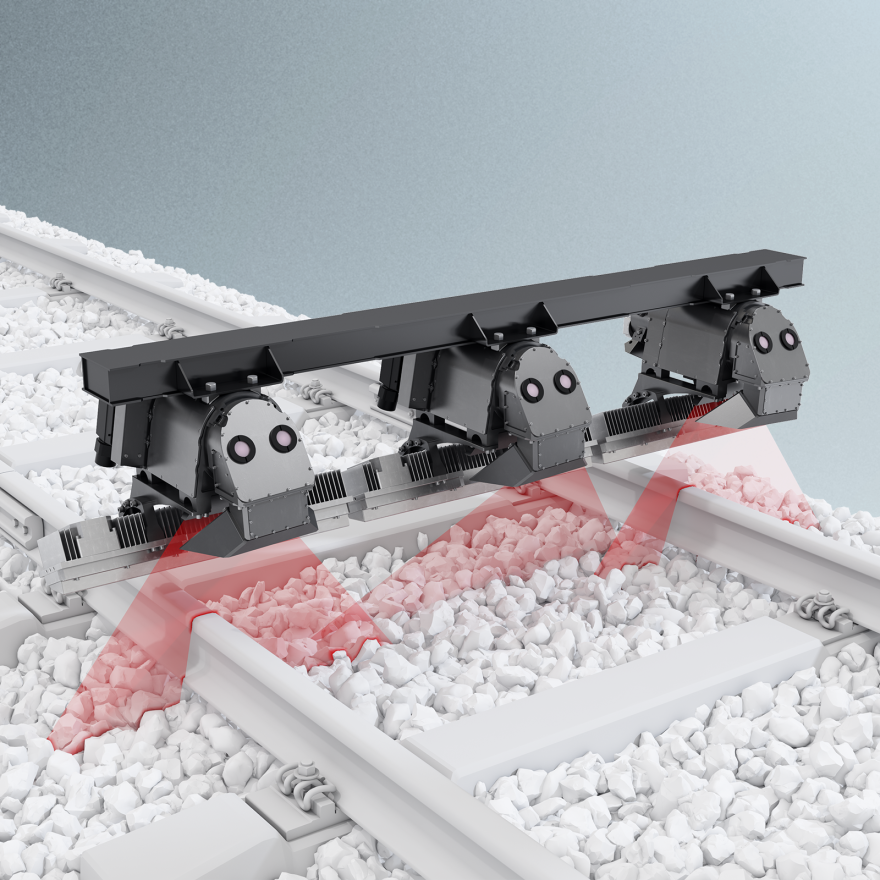

Track Inspection: V-CUBE

The growing need for track inspections and measurements often results in multiple systems. V-CUBE simplifies this with an All-in-One solution, enabling in-motion, contactless acquisition of multiple parameters. It identifies over 50 defect types on the rolling surface, fastenings, sleepers, and track bed, with superior detection rates. Installed on diagnostic and revenue trains, V-CUBE captures images at speeds up to 200 km/h and uses advanced algorithms to process and detect defects through a model-based approach.

Track Inspection: V-CUBE

The growing need for track inspections and measurements often results in multiple systems. V-CUBE simplifies this with an All-in-One solution, enabling in-motion, contactless acquisition of multiple parameters. It identifies over 50 defect types on the rolling surface, fastenings, sleepers, and track bed, with superior detection rates. Installed on diagnostic and revenue trains, V-CUBE captures images at speeds up to 200 km/h and uses advanced algorithms to process and detect defects through a model-based approach.

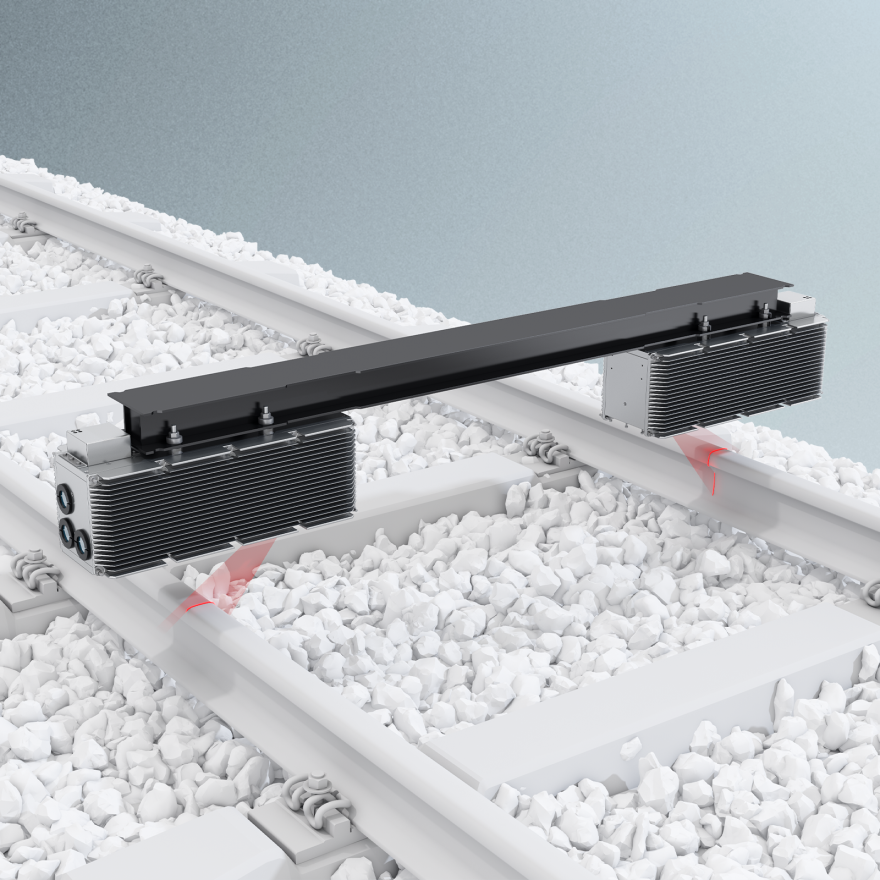

Head Check Detection

New-generation rail steels are highly resistant to abrasion, but this can allow cracks like “head checks” to grow, threatening rail integrity. The Head Checks Detection System uses high-accuracy machine vision to detect these defects early, when re-grinding can still address them. It identifies sub-millimeter defects at inspection speeds up to 120 km/h, operating in any light or weather conditions.

Head Check Detection

New-generation rail steels are highly resistant to abrasion, but this can allow cracks like “head checks” to grow, threatening rail integrity. The Head Checks Detection System uses high-accuracy machine vision to detect these defects early, when re-grinding can still address them. It identifies sub-millimeter defects at inspection speeds up to 120 km/h, operating in any light or weather conditions.

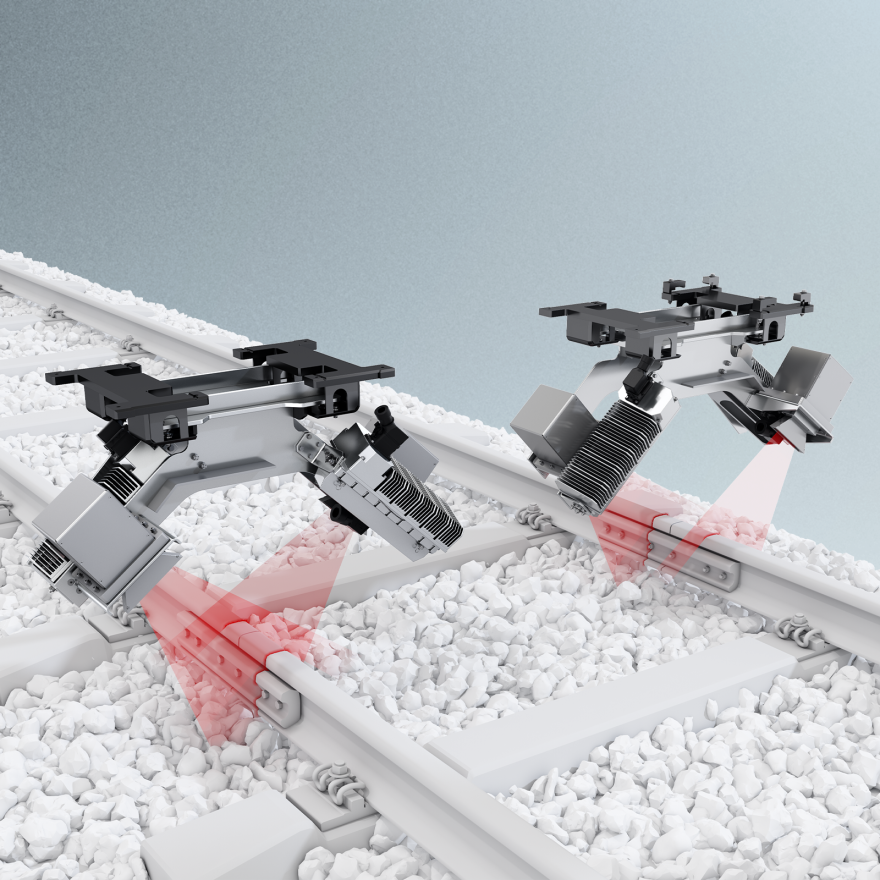

Fishplate / Joint bar Inspection

Failures in fishplates can have severe consequences, including rail joint misalignment and switch malfunctions. Key elements like cracks, missing bolts, corrosion, and welds must be inspected for safety. The Fishplate Inspection System detects defects automatically, including cracks and missing bolts, at speeds up to 320 km/h, using advanced algorithms for precise and reliable inspection.

Fishplate / Joint bar Inspection

Failures in fishplates can have severe consequences, including rail joint misalignment and switch malfunctions. Key elements like cracks, missing bolts, corrosion, and welds must be inspected for safety. The Fishplate Inspection System detects defects automatically, including cracks and missing bolts, at speeds up to 320 km/h, using advanced algorithms for precise and reliable inspection.

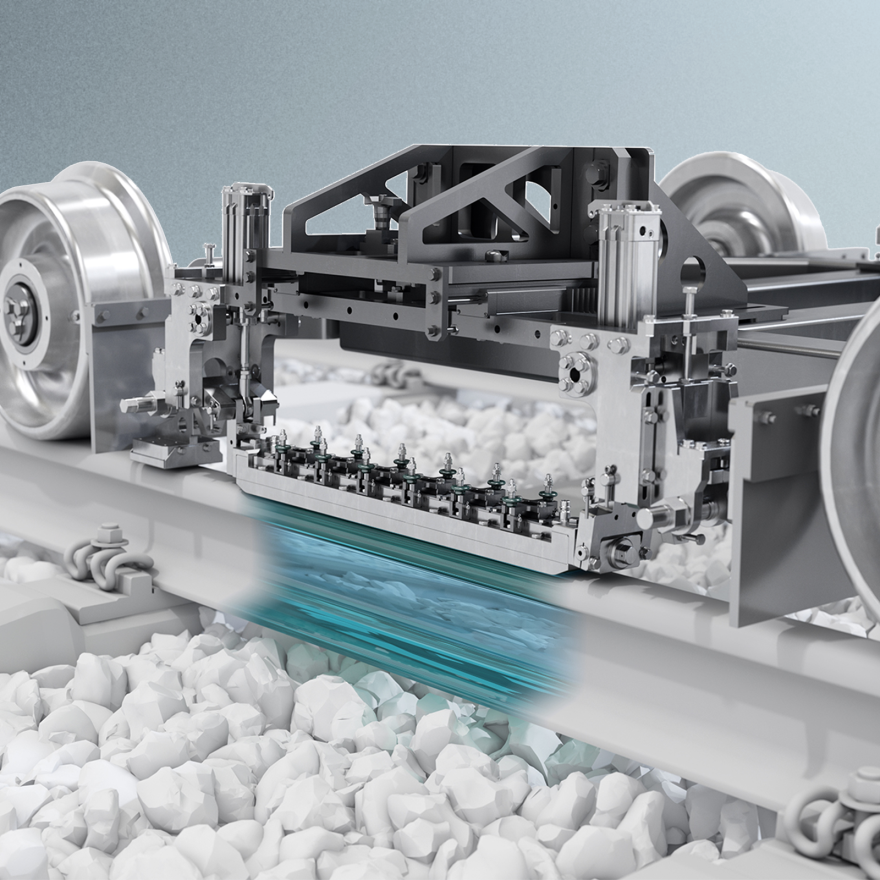

Internal Rail Flaw: Ultrasonic Inspection

The Rail Flaw Inspection System integrates high-speed, contactless technologies with advanced ultrasonic technology to detect internal rail defects, addressing limitations of vision systems. Mounted on a dedicated bogie, the system uses transducers to maintain proper contact with the rail, ensuring accurate inspections at speeds up to 100 km/h, depending on track conditions. This comprehensive assessment is crucial for identifying internal flaws and ensuring full infrastructure safety.

Internal Rail Flaw: Ultrasonic Inspection

The Rail Flaw Inspection System integrates high-speed, contactless technologies with advanced ultrasonic technology to detect internal rail defects, addressing limitations of vision systems. Mounted on a dedicated bogie, the system uses transducers to maintain proper contact with the rail, ensuring accurate inspections at speeds up to 100 km/h, depending on track conditions. This comprehensive assessment is crucial for identifying internal flaws and ensuring full infrastructure safety.

How can we help you?

We’re here to support you. Whether you have questions about MERMEC solutions or need specific information, our team is ready to assist. Reach out to us, and we’ll ensure you get the answers and guidance you need.

Get in touch