Steel & Industrial Applications

Steel & Industrial Applications Portfolio

The MERMEC Industrial Business Unit offers cutting-edge measuring solutions for the steel industry, including comprehensive dimensional inspection systems for hot rolled long products, seamless rolled rings, monoblock wheels, and open die forgings.

Hot Rolled Long Products

A complete range of measuring solutions for the automatic dimensional and surface inspections of bars, beams, rail and special profiles.

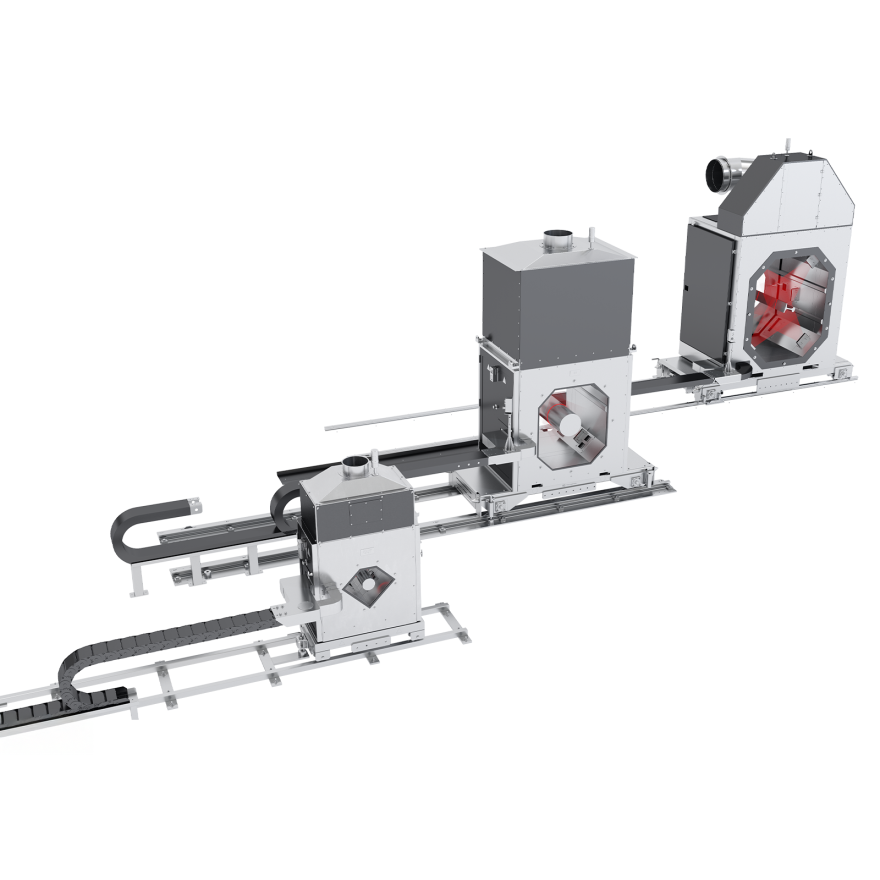

ProfileCheck Measuring System

Profilometer for on-line, dimensional measurement of hot rolled long products.

ProfileCheck is an optical system, based on laser triangulation technology, for the measurement of the complete profile, of key dimensions and shape of the full range of bars, beams, rails and special profiles. The system automatically identifies the main rolling defects thus enabling the user to correct in the real time the working parameters.

ProfileCheck Measuring System

Profilometer for on-line, dimensional measurement of hot rolled long products.

ProfileCheck is an optical system, based on laser triangulation technology, for the measurement of the complete profile, of key dimensions and shape of the full range of bars, beams, rails and special profiles. The system automatically identifies the main rolling defects thus enabling the user to correct in the real time the working parameters.

SurfaceCheck Inspection System

Advanced on-line surface inspection of hot rolled long products.

SurfaceCheck detects the required surface defects in a continuous way throughout the entire profile and the complete rolled piece. The system is based on the analysis and processing of the images acquired by a group of cameras at high resolution and high frame rate. Various occurring defects as projections, peelings, cracks and rolling marks, imprints, foldings, gouges, rolled-in particles and so on are grouped, case by case, under classes cross-matching specific descriptive criteria.

SurfaceCheck Inspection System

Advanced on-line surface inspection of hot rolled long products.

SurfaceCheck detects the required surface defects in a continuous way throughout the entire profile and the complete rolled piece. The system is based on the analysis and processing of the images acquired by a group of cameras at high resolution and high frame rate. Various occurring defects as projections, peelings, cracks and rolling marks, imprints, foldings, gouges, rolled-in particles and so on are grouped, case by case, under classes cross-matching specific descriptive criteria.

Dimensional Measurement

A complete range of solutions to measure hot or cold rings during in-line and offline operations.

RingCheck Measurement Station

Automatic dimensional check of hot rings during production.

The system is usually installed right after the finishing press to measure the full profile, the key dimensions and the quality parameters of the rolled piece.

RingCheck enables the user to correct, in real time, the working parameters, directly and automatically identifying the main rolling defects during the production phase. The 3D visualisation software shows out of tolerance dimensions and the localisation of excess and lack of material.

RingCheck Measurement Station

Automatic dimensional check of hot rings during production.

The system is usually installed right after the finishing press to measure the full profile, the key dimensions and the quality parameters of the rolled piece.

RingCheck enables the user to correct, in real time, the working parameters, directly and automatically identifying the main rolling defects during the production phase. The 3D visualisation software shows out of tolerance dimensions and the localisation of excess and lack of material.

RingCheck Quality Station

Automatic quality check of cold rings.

The complete profile, the key dimensions and the quality parameters of the rolled piece, such as shaped rings, flanges and sleeves, are automatically measured. Identifying any dimensional defects in real time, RingCheck enables the operator to make prompt decisions on ring destination and, at the same time, to give numerical indications for machining/finishing phase. System range counts both in-line and off-line applications.

RingCheck Quality Station

Automatic quality check of cold rings.

The complete profile, the key dimensions and the quality parameters of the rolled piece, such as shaped rings, flanges and sleeves, are automatically measured. Identifying any dimensional defects in real time, RingCheck enables the operator to make prompt decisions on ring destination and, at the same time, to give numerical indications for machining/finishing phase. System range counts both in-line and off-line applications.

Monoblock Wheels

Measuring solutions for the complete dimensional check of hot, raw and finished monoblock wheels.

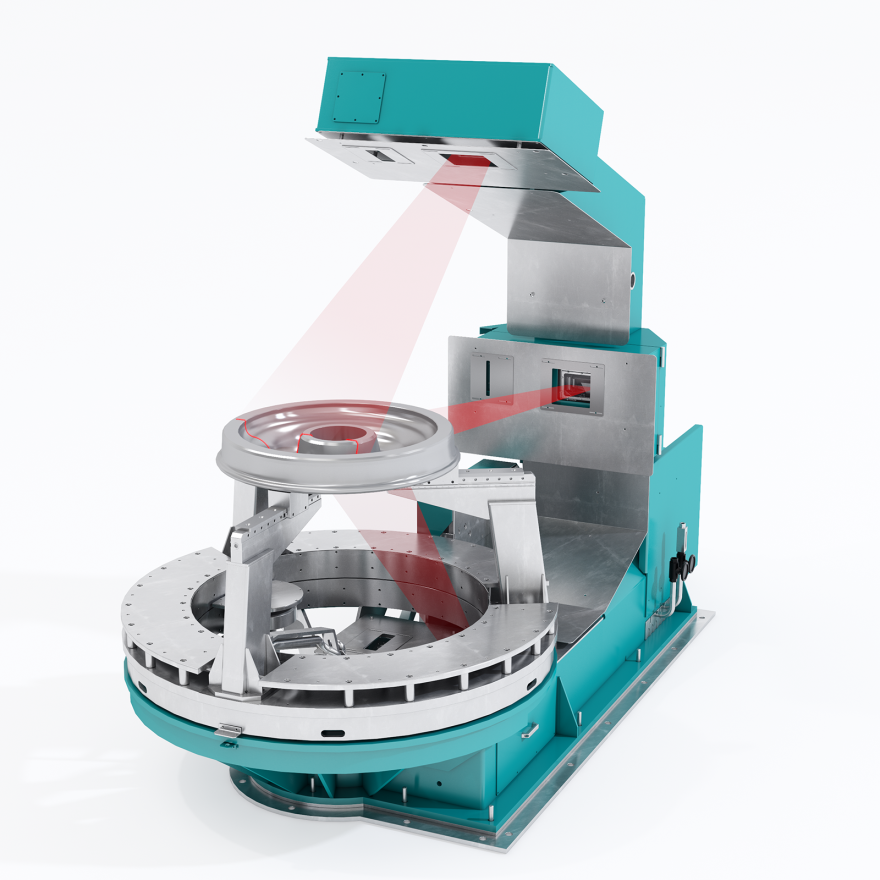

WheelCheck Measurement Station

Automatic dimensional check of hot wheels during production.

The system is usually installed right after the finishing press to measure the full wheel profile and wheel diameters, the key dimensions and the wheel quality parameters. WheelCheck enables the client to correct, in real time, the working parameters, directly and automatically identifying the main rolling defects during the production phase. The 3D visualisation software shows out of tolerance dimensions and the localisation of excess and lack of material.

WheelCheck Measurement Station

Automatic dimensional check of hot wheels during production.

The system is usually installed right after the finishing press to measure the full wheel profile and wheel diameters, the key dimensions and the wheel quality parameters. WheelCheck enables the client to correct, in real time, the working parameters, directly and automatically identifying the main rolling defects during the production phase. The 3D visualisation software shows out of tolerance dimensions and the localisation of excess and lack of material.

WheelCheck Quality Station

Automatic dimensional check of raw and finished monobloc wheels.

WheelCheck is an optical, non-contact system, based on laser triangulation technology, for the complete dimensional measurement of the monobloc wheels varying in flange diameter up to 1400mm. The complete profile, all the key dimensions and run out circularity of the wheels are automatically measured according to EN13262 requirements. The key dimensions of all the wheel holes are obtained by integrating the HolesCheck contact measurement system.

Identifying any dimensional defects in real time, WheelCheck enables the operator to make prompt decisions on wheel destination.

WheelCheck Quality Station

Automatic dimensional check of raw and finished monobloc wheels.

WheelCheck is an optical, non-contact system, based on laser triangulation technology, for the complete dimensional measurement of the monobloc wheels varying in flange diameter up to 1400mm. The complete profile, all the key dimensions and run out circularity of the wheels are automatically measured according to EN13262 requirements. The key dimensions of all the wheel holes are obtained by integrating the HolesCheck contact measurement system.

Identifying any dimensional defects in real time, WheelCheck enables the operator to make prompt decisions on wheel destination.

Open Die Forgings

A wide and versatile range of accurate and remote measuring systems serving forging operations. The range counts applications for the under press 2D measurement or visual control and for full 3D reconstruction of the forged pieces.

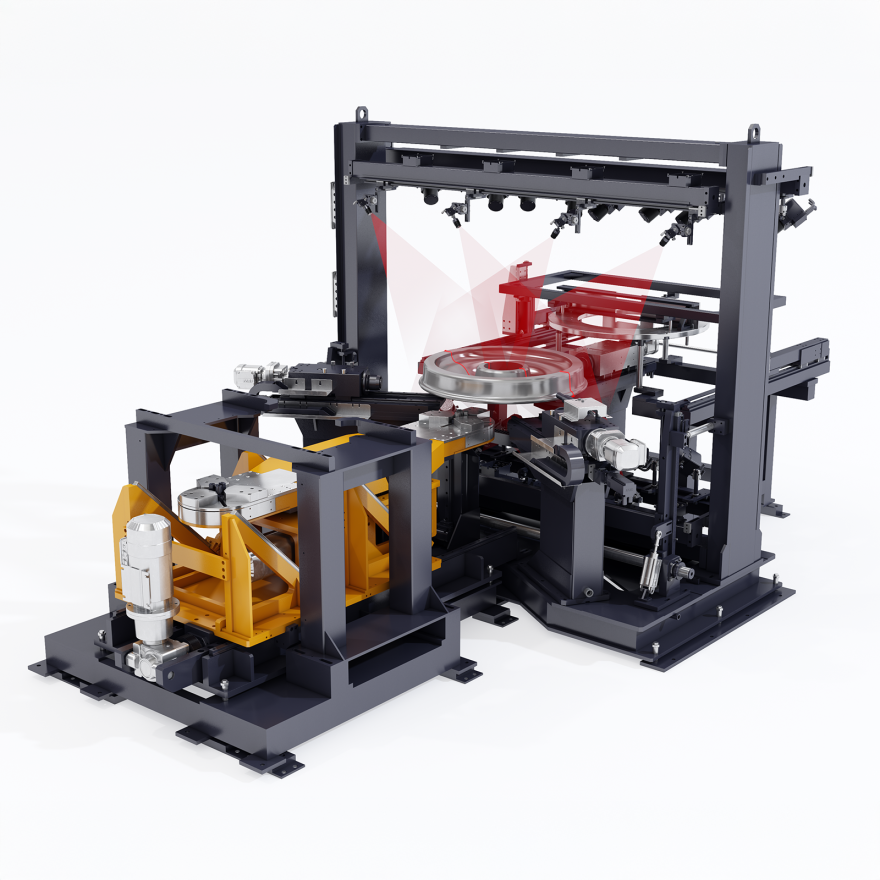

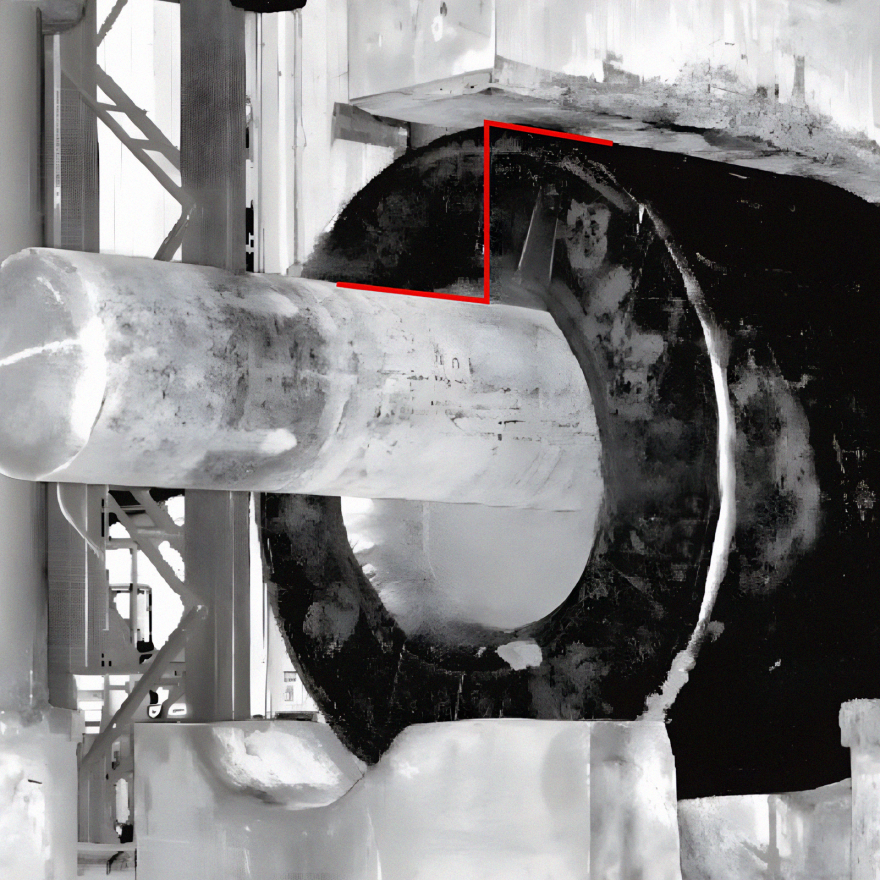

3D Portal

Measuring system for the 3D survey and dimensional check of hot or cold forgings.

3D PORTAL is an optical system, based on phase shift ranging, for the 3D survey and automatic dimensional check of hot or cold open die forgings according to use in the forging phase or in the finishing working process. The system, thanks to its flexible configuration, can be employed for the dimensional measurement of a wide range of open-die forgings, both axial-symmetric and special pieces, even for high-duty applications.

3D Portal

Measuring system for the 3D survey and dimensional check of hot or cold forgings.

3D PORTAL is an optical system, based on phase shift ranging, for the 3D survey and automatic dimensional check of hot or cold open die forgings according to use in the forging phase or in the finishing working process. The system, thanks to its flexible configuration, can be employed for the dimensional measurement of a wide range of open-die forgings, both axial-symmetric and special pieces, even for high-duty applications.

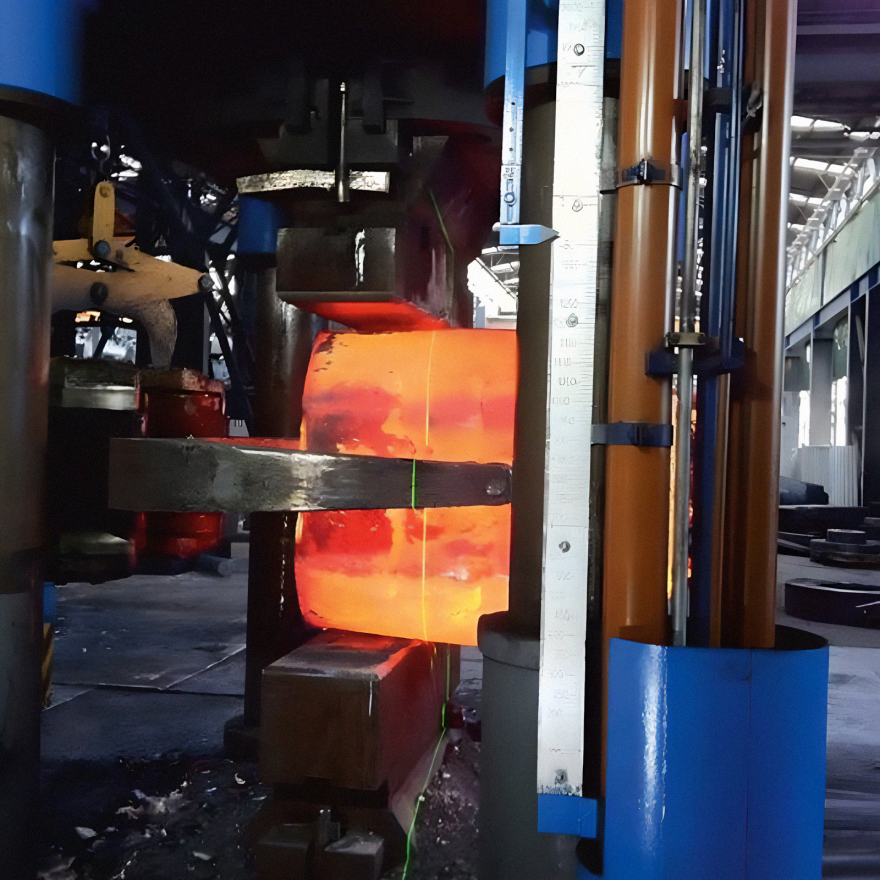

Laser Aid Forging (LAF) Equipment

Green lasers for visual dimensional control under press.

Visible vertical sliding lasers to support manual length measurement and visible horizontal laser for the continuous control of thickness, length, heights, alignment and straightness that provide operators with visible assistance to forging operations.

Laser Aid Forging (LAF) Equipment

Green lasers for visual dimensional control under press.

Visible vertical sliding lasers to support manual length measurement and visible horizontal laser for the continuous control of thickness, length, heights, alignment and straightness that provide operators with visible assistance to forging operations.

Real Time Monitoring (RTM) Equipment

Measuring systems for the under press real time monitoring of forgings.

RTM Equipment enables the real time monitoring of specific geometric quotes of the forged pieces directly under press. By exploiting different measuring techniques and designing different SW, mechanical and optical configurations MERMEC has designed a complete product ranges according to the shape of the pieces to be measured combined to the specific forge layout. Compatible with: squares, shafts and other complex profiles, rounds, shells.

Real Time Monitoring (RTM) Equipment

Measuring systems for the under press real time monitoring of forgings.

RTM Equipment enables the real time monitoring of specific geometric quotes of the forged pieces directly under press. By exploiting different measuring techniques and designing different SW, mechanical and optical configurations MERMEC has designed a complete product ranges according to the shape of the pieces to be measured combined to the specific forge layout. Compatible with: squares, shafts and other complex profiles, rounds, shells.

How can we help you?

We’re here to support you. Whether you have questions about MERMEC solutions or need specific information, our team is ready to assist. Reach out to us, and we’ll ensure you get the answers and guidance you need.

Get in touch