Measurement Trains & Systems

Catenary Measurement

Laser scanners and high-resolution cameras accurately measure critical catenary parameters.

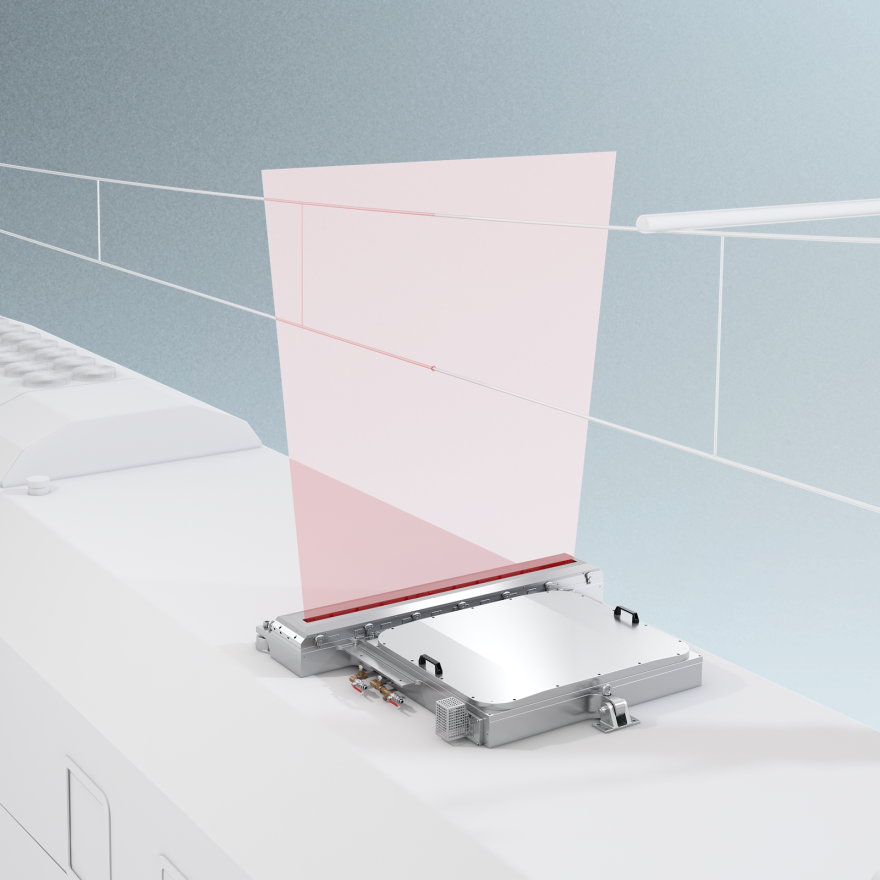

Geometry & Contact Wire Wear

The Catenary Geometry & Wear System ensures the health of catenary infrastructure by measuring height, residual thickness, and stagger of up to 8 wires simultaneously at speeds up to 320 km/h. Using laser scanners and high-resolution cameras, it captures over 5,000 measurements per second, detecting wear and damage caused by pantograph interactions, temperature changes, or infrastructure failures. The system offers precise, non-contact measurements to extend contact wire lifespan and improve safety, with customizable sampling for pinpointing weak spots.

Geometry & Contact Wire Wear

The Catenary Geometry & Wear System ensures the health of catenary infrastructure by measuring height, residual thickness, and stagger of up to 8 wires simultaneously at speeds up to 320 km/h. Using laser scanners and high-resolution cameras, it captures over 5,000 measurements per second, detecting wear and damage caused by pantograph interactions, temperature changes, or infrastructure failures. The system offers precise, non-contact measurements to extend contact wire lifespan and improve safety, with customizable sampling for pinpointing weak spots.

Electric Parameters: Voltage and Drained Current

The system enables real-time assessment of the electric power drained from the contact wire by measuring key electric parameters, including voltage and current. It operates in all environmental conditions, providing real-time visualization of traction voltage and current absorbed by rolling stock. The system can be installed on any railway vehicle, either in attended or unattended mode, and operates at speeds up to 320 km/h, using onboard software for continuous data analysis and measurement of electrical parameters.

Electric Parameters: Voltage and Drained Current

The system enables real-time assessment of the electric power drained from the contact wire by measuring key electric parameters, including voltage and current. It operates in all environmental conditions, providing real-time visualization of traction voltage and current absorbed by rolling stock. The system can be installed on any railway vehicle, either in attended or unattended mode, and operates at speeds up to 320 km/h, using onboard software for continuous data analysis and measurement of electrical parameters.

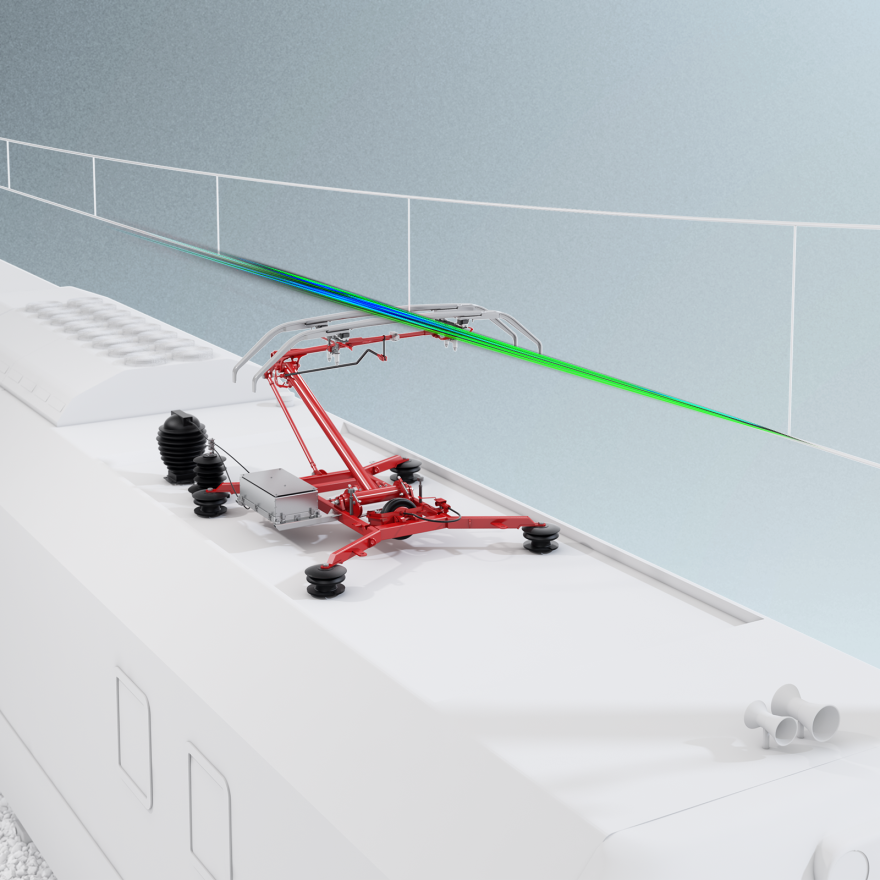

Pantograph / Catenary Interaction Measuring System

The Pantograph / Catenary Interaction Measuring System monitors interaction forces between the pantograph and contact wire using accelerometers and load cells. It measures static and dynamic forces, vertical accelerations, and catenary height and stagger, with a dynamic sampling frequency of up to 2 kHz at speeds up to 320 km/h. The system detects potential issues like loss of contact and arcing, ensuring proper energy supply and preventing deterioration, and can be integrated with other catenary measurement systems.

Pantograph / Catenary Interaction Measuring System

The Pantograph / Catenary Interaction Measuring System monitors interaction forces between the pantograph and contact wire using accelerometers and load cells. It measures static and dynamic forces, vertical accelerations, and catenary height and stagger, with a dynamic sampling frequency of up to 2 kHz at speeds up to 320 km/h. The system detects potential issues like loss of contact and arcing, ensuring proper energy supply and preventing deterioration, and can be integrated with other catenary measurement systems.

Electric Arc Detection

The Electric Arcs Detection System (EADS) detects and evaluates electrical arcs between the pantograph and contact wire, which are more common at high speeds, heavy loads, and in cold conditions. Arcing distorts supply voltage and current, generating interference across the railway system. EADS operates at speeds up to 320 km/h, distinguishing arcing from scintillation using threshold filtering. It correlates arc data with contact line measurements and uses light filters to remain effective in all weather conditions, even under sunlight.

Electric Arc Detection

The Electric Arcs Detection System (EADS) detects and evaluates electrical arcs between the pantograph and contact wire, which are more common at high speeds, heavy loads, and in cold conditions. Arcing distorts supply voltage and current, generating interference across the railway system. EADS operates at speeds up to 320 km/h, distinguishing arcing from scintillation using threshold filtering. It correlates arc data with contact line measurements and uses light filters to remain effective in all weather conditions, even under sunlight.

Contact Wire Thermal Scanning

The Thermal Scan Monitoring System uses infrared imaging to detect early temperature rises in overhead catenaries, preventing overheating and sagging that can block train lines. It operates at high speed, measuring temperatures from 40°C to 500°C. The system, rugged enough for outdoor use, helps avoid costly breakdowns and downtime by identifying issues before they cause failures. It can be integrated with a Catenary Video Surveillance system for high-resolution color images and thermal data, enhancing monitoring and maintenance.

Contact Wire Thermal Scanning

The Thermal Scan Monitoring System uses infrared imaging to detect early temperature rises in overhead catenaries, preventing overheating and sagging that can block train lines. It operates at high speed, measuring temperatures from 40°C to 500°C. The system, rugged enough for outdoor use, helps avoid costly breakdowns and downtime by identifying issues before they cause failures. It can be integrated with a Catenary Video Surveillance system for high-resolution color images and thermal data, enhancing monitoring and maintenance.

How can we help you?

We’re here to support you. Whether you have questions about MERMEC solutions or need specific information, our team is ready to assist. Reach out to us, and we’ll ensure you get the answers and guidance you need.

Get in touch