Measurement Trains & Systems

Catenary Inspection

Automated image processing detects defects in overhead line components with precision.

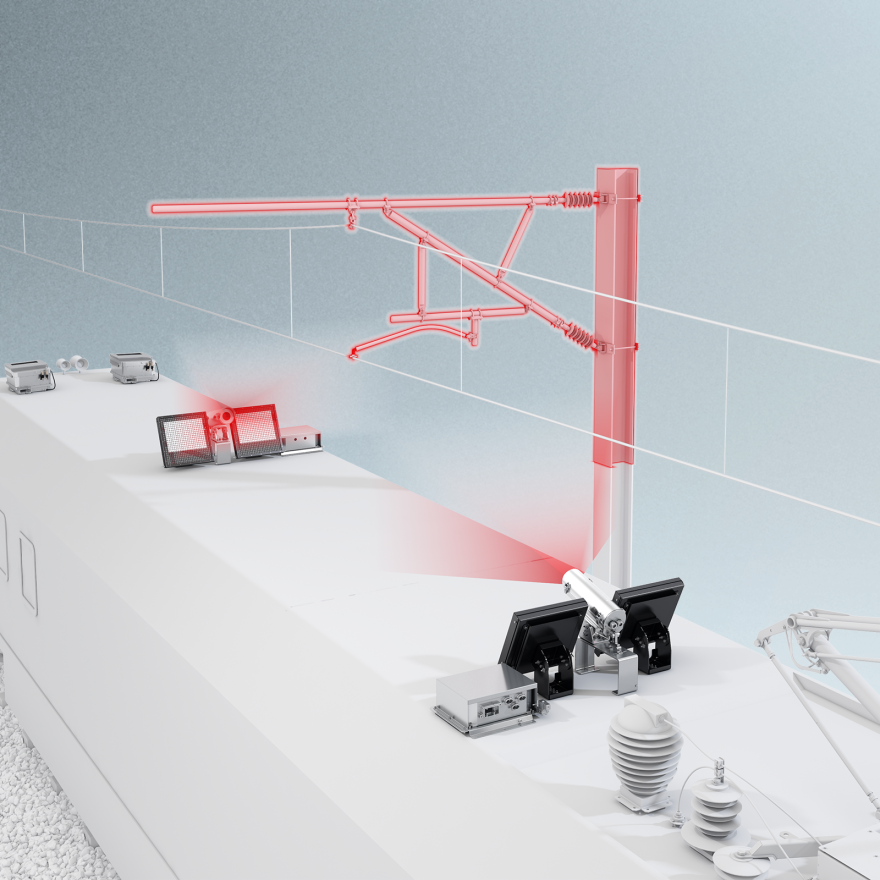

Longitudinal Defects Detection System

The Longitudinal Defects Detection System inspects catenary infrastructure components along the track’s longitudinal axis, such as catenary ropes, contact wires, droppers, fixed points, and insulators. It detects changes in these elements, ensuring catenary safety. The system uses high-performance vision algorithms to extract key parameters and generate defect reports. Data from catenary geometry measurement systems can be cross-referenced to enhance analysis and accuracy.

Longitudinal Defects Detection System

The Longitudinal Defects Detection System inspects catenary infrastructure components along the track’s longitudinal axis, such as catenary ropes, contact wires, droppers, fixed points, and insulators. It detects changes in these elements, ensuring catenary safety. The system uses high-performance vision algorithms to extract key parameters and generate defect reports. Data from catenary geometry measurement systems can be cross-referenced to enhance analysis and accuracy.

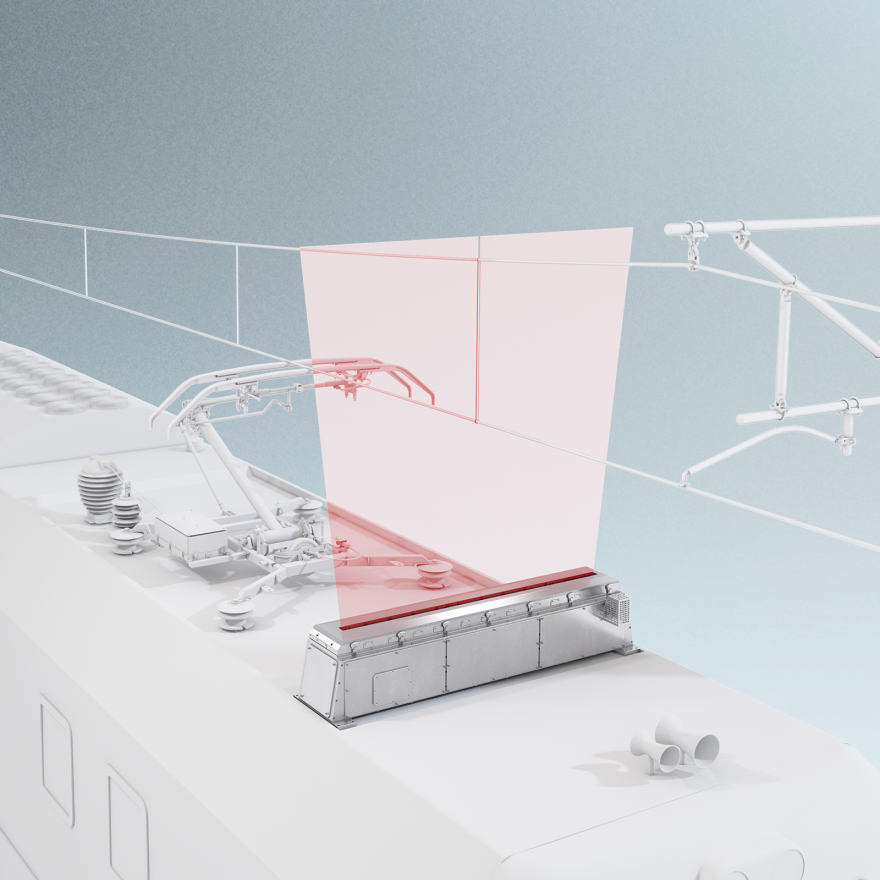

Transversal Defects Detection System

The Transversal Defects Detection System, along with Longitudinal Defect Detection, identifies overhead line components and potential failures. Using high-resolution cameras and powerful illumination, it captures images of cantilevers, line hangers, and insulators, detecting changes or corrosion. The system employs double-sided imaging, triggered by the Pole Detection System, and automatically associates defects with their exact position on the track. The images are saved for further evaluation by technicians, ensuring precise fault tracking.

Transversal Defects Detection System

The Transversal Defects Detection System, along with Longitudinal Defect Detection, identifies overhead line components and potential failures. Using high-resolution cameras and powerful illumination, it captures images of cantilevers, line hangers, and insulators, detecting changes or corrosion. The system employs double-sided imaging, triggered by the Pole Detection System, and automatically associates defects with their exact position on the track. The images are saved for further evaluation by technicians, ensuring precise fault tracking.

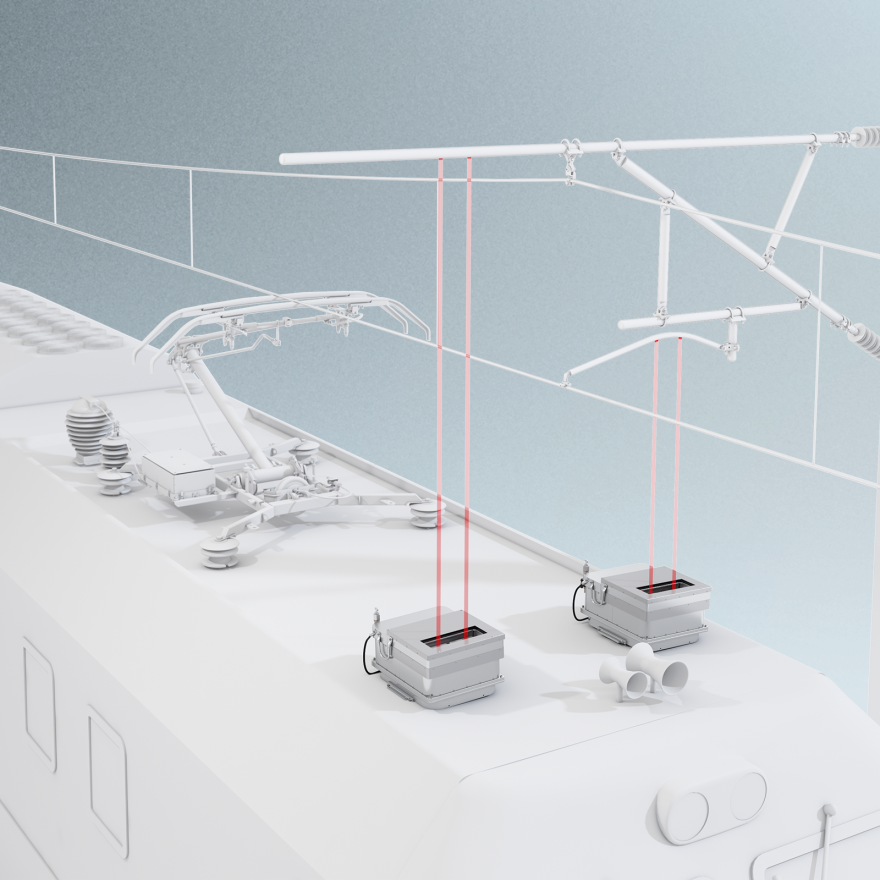

Pole Detection

The Pole Detection System locates defective sections by identifying the two poles at each end. It continuously detects the catenary wire support structure along the track, allowing for precise fault positioning. Mounted on the inspection car’s rooftop, each unit uses two vertically oriented laser-based distance measurement systems. The system calculates the distance to objects by analyzing the phase shift of the reflected laser beam. It records a pole when both beams reflect simultaneously, ensuring accurate positioning of defects.

Pole Detection

The Pole Detection System locates defective sections by identifying the two poles at each end. It continuously detects the catenary wire support structure along the track, allowing for precise fault positioning. Mounted on the inspection car’s rooftop, each unit uses two vertically oriented laser-based distance measurement systems. The system calculates the distance to objects by analyzing the phase shift of the reflected laser beam. It records a pole when both beams reflect simultaneously, ensuring accurate positioning of defects.

How can we help you?

We’re here to support you. Whether you have questions about MERMEC solutions or need specific information, our team is ready to assist. Reach out to us, and we’ll ensure you get the answers and guidance you need.

Get in touch